William Orvis

LUNAR# 309

If you bought one of the original MicroMacxx® rockets, it came with its own launch pad, launch controller, and igniter holder. If your club has a set of standard launch pads, this pad and controller does not really work well with them. Also, newer MicroMaxx® rockets with clustered engines don’t work at all with the single igniter holders in the original pad.

This article describes how to build a MicroMaxx® launch rod that can be used with any clubs launch system. Our club uses Panavices® to hold and tilt the launch rods so all of our launch rods, including the MicroMaxx® rods, have a 5/8 inch adapter to fit the Panavice™. If your club uses a different attachment method, just change the adapter to one that fits your club’s equipment.

The first step in building a MicroMaxx® launch rod is finding wire to make the rod itself. MicroMaxx® rockets have 1/16 inch launch lugs so the launch rod has to be slightly smaller than that. It also has to be very stiff so most wire you would find at the hardware store is out of the question. What we use is 0.039 music wire for model airplane servos. This is the wire that goes from a servo to the control surface to make it move when the servo moves. This wire is 0.039 inch diameter and extremely stiff. You can get it anywhere that sells remote controlled model airplanes. I guess it is also for pianos but it is easier to get at a hobby store.

As mentioned above, our launch pads use a Panavice® to hold the launch rod. A Panavice® is designed to clamp onto a 5/8 inch rod so we start with a 3 inch piece of 5/8 rod stock. If your launch equipment uses a different sized clamp, change this piece to one that fits your equipment. Carefully drill a 1/16 inch hole about ½ inch into the center of one end of the 5/8 rod.

Cut an 18 inch piece of music wire and make sure both ends are smooth and straight. If either end was bent by the cutting process, grind off the bent part with a bench grinder until it is clean and straight. Any kind of a bend or snag at the end of the launch rod could snag the rocket as it is launching and really spoil your day. I initially made some 12 inch launch rods, equivalent to the old MicroMaxx® pads but find the 18 inch ones give better results as they give the rocket little more time to come up to speed.

Insert the music wire into the 1/16 hole on the end of the 5/8 rod and solder it in place. You will need to solder this with a torch as a soldering iron cannot get the 5/8 rod hot enough to stick. When heating the workpiece, only play the flame on the 5/8 rod until the solder flows. Don’t directly head the music wire as that will soften it.

I heated the 5/8 rod until the solder wets the top of the rod. I then held the music wire straight with some pliers and sprayed the top of the 5/8 rod with water to more quickly cool and harden the solder. Cooling the music wire quickly also rehardens it where you might have softened it by the heating.

The next step is to protect the launch rod both from damage while it is being stored and for people’s eyes while it is being transported. I built in the protection using a piece of 1 inch PVC pipe and two end caps.

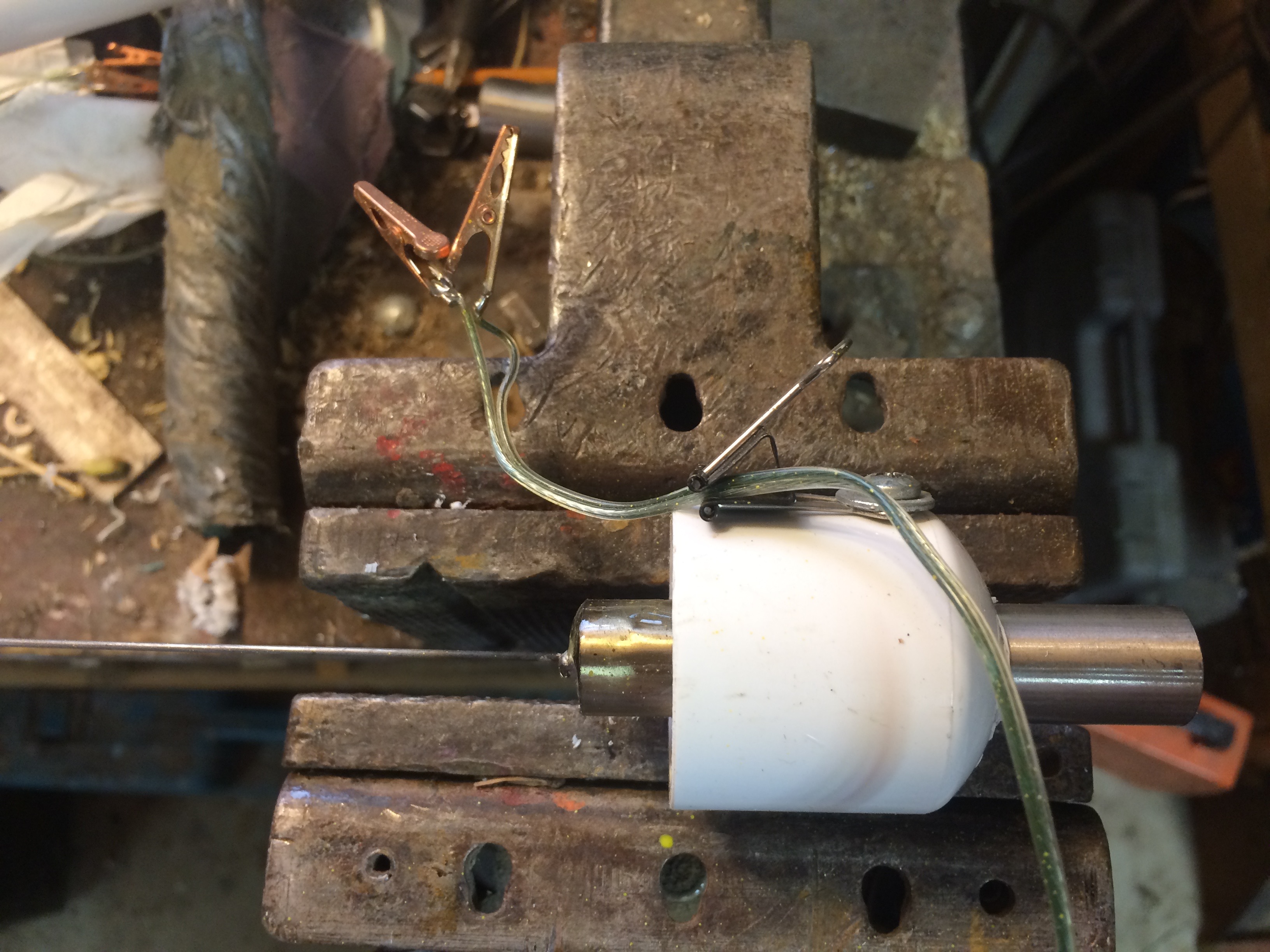

Drill a 5/8 hole in one end cap and inserted the 5/8 rod through it, letting it hang an inch below the bottom of the cap. You are going to pour epoxy down into the end cap to secure it to the 5/8 rod so first put masking tape on the inside of the cap, where the pipe would touch it, to keep the epoxy off that contact surface. Then, pour epoxy down into the end cap, securing it to the 5/8 rod. See figure 1.

Figure 1. The 5/8 rod with the piano wire soldered in the top and the PVC end cap ready to be glued in place. Note the tape on the inside of the cap to prevent the glue from getting on the inside surface of the cap.

While the epoxy was curing, I cut a 20 inch piece of 1 inch PVC pipe and stuck the second end cap on it. If the end cap does not fit tight, glue it in place.

When the epoxy is hard, remove the masking tape from the inside of the end cap. You can now slide the piece of PVC pipe over the launch rod and into the end cap. Do not glue this piece as it is only for protection while it is stored or being transported and must be removable when using it to launch a rocket. See figure 2.

Figure 2. The completed MicroMaxx® launch rod in its protective covering.

Remove the pipe and spray a thin coat of yellow paint on the tip of the rod. This makes it easier to see and less likely to poke out someone’s eye. Make sure the paint is very thin and does not bind in a MicroMaxx® launch lug.

MicroMaxx® igniters tend to be really lightweight and can easily pull out of the bottom of an engine. Igniter clips designed for A, B, C and larger engines can be too heavy for the lightweight igniters used for MicroMaxx®. To fix this problem, make a lightweight igniter clip with small alligator clips and a few inches of #22 wire. Don’t use more than 6 inches of #22 wire or the internal resistance will eat up all your power and it will not fire the igniter. I have had no problem with 6 inch leads. Add a paper clamp to the bottom of the launch rod to hold the igniter clip and keep its weight off of the igniter. See figure 3.

Figure 3. The end cap glued in place with a paper clamp to hold the lightweight igniter clip.

To use these new launch rods, simply clamp them into the Panavice® and slide off the pipe to expose the rod. Slide your rocket down the launch rod and clip onto it with the light weight clips. Clip the normal launch clips onto the end of the lightweight clips and let her rip. See Figure 4.

Figure 4. A 2 stage MicroMaxx® rocket ready to fly.

Be sure to slide the pipe over the rod as soon as is practical after launching a rocket to both protect the rod from being bent and to protect people’s eyes around the rod as it is very difficult to see.

Micromaxx is a registered trademark of Quest Aerospace, Inc.

Panavice is a registered trademark of Panavise Products, Inc.